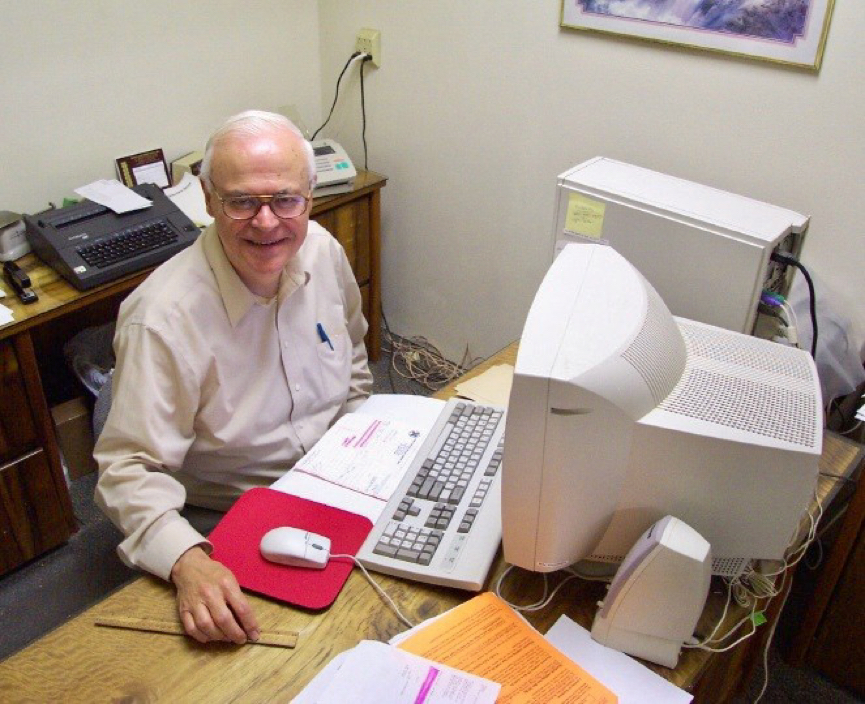

I learned a lot from [Tracy Hassett]. He was critical to my education as a woodworker. We remained friends till he moved from Oregon to Utah. … I would love to see him again. Hassett was the Wooden Nickel. He built it from scratch. He set the standards of Wooden Nickel quality.

ARTIST RICK COOK

Harvey Johnston and the Reinholds continued Hassett’s standards and did a good job doing so.

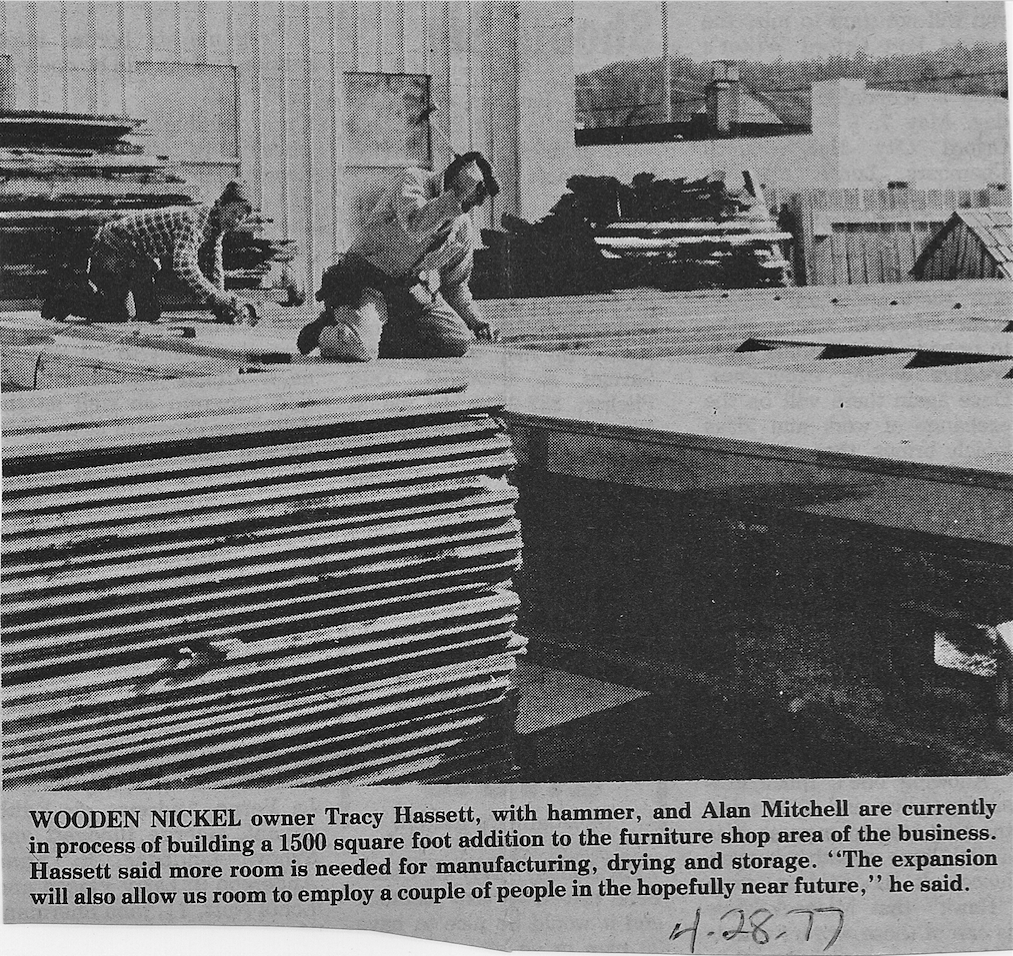

Tracy Hassett started construction of the Wooden Nickel October 1973 and opened May 1974. There was an old two-story turn of the century house on the lot the Nickel was built. Tracy chose Port Orford to build because he was able to buy commercial property on 101 at a very reasonable price compared to Brookings. He thought Port Orford had promise. Tracy sold to Johnston and the Reinholds in 1993. Opened Pacific Myrtlewood in 94/95 and moved to Utah in 2005.

Tracy logged for South Coast Lumber Co. Brookings, Oregon before coming to Port Orford. Much of the Myrtlewood lumber the Wooden Nickel used was logged by South Coast and milled by Abe Hanks in Nesika Beach.

Tracy set a high standard for quality and was respected by his employees for doing so. His thin and light weight bowls were the finest turned of any found in Myrtlewood shops on the coast.

For all its apparent abundance in shop after shop along the coast, the wood is apparently destined to become increasingly rare. Describing the situation, Tracy Hassett, a former logger who produces and sells myrtlewood at the Wooden Nickel in Port Orford, said: “The supply is definitely going to be diminishing. There’s a sufficiency now, but probably within 8 to 10 years, we’re going to start seeing a shortage.

“Even now, it’s hard to get really nice pieces. The quality is diminishing because the largest trees have already been cut. We’re having to go to smaller trees that don’t have the color.”

JOAN CHATFIELD-TAYLOR, “SILKY MYRTLEWOOD OF THE OREGON COAST” (NEW YORK TIMES, MARCH 13 1987)

According to Mr. Hassett, it takes between 150 and 200 years for a myrtle to grow a trunk 16 inches in diameter. Even though the wood is usually cut in vertical slabs rather than across the trunk, it is difficult to get the large pieces of wood necessary for big bowls and platters. John Shreck searched for two years for the right slice of wood to make a 20-inch salad bowl for a client

The Wooden Nickel manufactured and retailed in its store a wide assortment of myrtlewood products including: handbells and Christmas tree ornaments; plates; platters; salad bowls of all sizes; cutting boards; goblets; appetizer trays; vases (glass lined), stamp boxes; pepper mills; candlestick holders; pedestal cake platters; disc-shaped plaques; salad serving spoons and tongs; napkin holders; serving plate tray; Myrtlewood and Redwood perfume, and Communionware (collection plates and Communion plates). Every product would be hand sanded and finished in one of two ways: An Epoxy finish for durability; and an Oiled finish for customers who preferred wood to be natural.

While harvesting the more useful and abundant Douglas fir, myrtle trees are of little interest to timber companies. Fortunately, when it’s profitable to do so, the myrtle trees are logged and set aside for delivery to small sawmills. These mini-mills cut the logs into easier to manage lumber or planks for artisans and businesses like the Wooden Nickel.

Leon White Remembers the Nickel

(A Series of Recollections by former Mayor Leon White as told to Alan Mitchell)

For at least the first 4-5 years, the Wooden Nickel was the City’s Greyhound Bus stop. Well before the days of UPS, the fastest means of shipping items and documents was by Greyhound. Between selling tickets and dealing with the various parcels coming and going, Leon recalls there having been extensive paperwork involved.

Regarding the Wooden Nickel Myrtlewood perfume, one of the bus drivers mentioned to Leon that after a passenger accidentally spilled some of the perfume on his bus, its distinctive fragrance lingered for days!

At the Wooden Nickel, making bowls begins with tracing patterns onto the Myrtlewood lumber. The patterns are then bandsawed into lathe-ready bowl blocks. Each of the bowl blanks has to be turned twice in order to account for the lumber’s natural shrinkage and warping as it dries out. The initial rough turning is necessary because the grain of the wood lies in different directions, resulting in each piece having different stress points. Round shapes put into the drying room will become elongated or distorted. Because myrtlewood is a hardwood, it is much easier to shape into bowls while still ‘green’ and filled with moisture.

From the initial rough turn, to a second and final turn, approximately 6 weeks will have elapsed. This much time in the dry kiln is necessary for the wood to become stable.

Standing at attention along the north wall of the store were usually a couple of Lyle Knutson’s heirloom quality Myrtlewood Grandfather and Grandmother clocks. During the day the store would be filled with the sound of Westminister chimes. Leon recalls that at times “he felt like he was in London”. When a clock purchaser needed to have their precious purchase shipped home, Tracy Hassett would build them a custom packing crate and Leon would take care of the shipping arrangements. “Pyrography by Judy” (Myrtlewood – Judy Hallek) was also a good seller in the store.

Along with Hassett (Owner), the original team at Wooden Nickel consisted of Red Thompson (Sales Representative), Lonnie Mecum, Rita Hunt, Laureen Purkey, Irene Baker, Betty Griffin, Rick Cook, Kathy Dahrens, Anna Thomas and Georgine Fields.

As the sign outside reads “See it Made”, the Wooden Nickel encouraged its retail customers to ask a salesclerk for a tour of its woodshop.

Leave a Reply